You’ve chosen Cortizo sliding doors. Smart move. They look stunning—huge glass panels, slim frames, and minimal sightlines.

The challenge? Finding the right supplier.

Two companies can quote the identical Cortizo system, but one delivers doors that work perfectly for 30 years while the other creates problems within five. The difference is engineering integrity.

The Interlock Decision

Every Cortizo Cor Vision door uses an interlock to join the panels. Cortizo offers two options: the standard flush interlock (COR-4326) and the reinforced version (COR-4327).

Most installers default to the standard option because it’s cheaper and simpler. For small doors in sheltered spots, it performs fine. The issue emerges with larger openings or exposed locations.

The reinforced interlock delivers over five times the structural strength—109.68 cm⁴ moment of inertia versus 20.52 cm⁴. This means vastly better resistance to wind-induced bending, preventing sticking doors, failed seals, and rattling panels.

We use the reinforced interlock as standard on every project.

The Question Nobody’s Asking You

Has anyone actually calculated the wind loads for your specific doors?

Not guessed. Not used “typical maximums” from the catalogue. Actually sat down with your project details and done the maths?

Because here’s what matters: your exact location (coastal, urban, rural), your door size and how many panels, how high up the building you are, and which direction your doors face.

We calculate wind loads for every single project.

By take your site conditions, run them through Cortizo’s structural performance data, we can work out exactly what your doors need to handle. If the reinforced interlock is enough, brilliant. If you need additional strengthening, we’ll tell you exactly what and why—with the calculations to prove it.

Most people think glass is just glass. It sits in the frame, you look through it, job done. Wrong.

In a properly engineered sliding door, the glass is working. It’s sharing loads, resisting wind pressure, and keeping the entire door rigid. That only happens if it’s specified correctly.

Structural Silicone

Only using structural silicone sealed units is what we do. This means the glass is permanently bonded to the aluminium frame, creating one solid structure.

Why does this matter?

With structural silicone:

- The glass actively helps stiffen the frame

- Loads spread evenly across the whole panel

- Nothing moves, rattles, or even shifts over time

- The door stays weather-tight for decades

Without it (dry-glazed or basic bonding):

- The glass just sits in the frame

- It can move slightly over time

- Seals degrade faster

- You get drafts, rattles and eventually leaks.

We see this all the time with doors that are only 5-10 years old. Someone cut corners on the glazing spec, and now the doors need completely rebuilding

Structural Glazing Matters

The glass in your doors is a structural component, not just a window. We exclusively use structural silicone sealed units, creating a permanent bond between glass and frame. This allows the glazing to contribute to overall door rigidity while distributing loads evenly.

Basic dry-glazed units might look identical initially, but they shift over time, causing seal failure and hardware wear.

The Right Glass Thickness For Your Doors

Glass thickness isn’t one-size-fits-all. We match it to your specific door size and exposure.

Small doors, sheltered sites: 6mm/6mm toughened glass

Larger doors or moderate exposure: 8mm/6mm

High-performance installations: 8mm/8mm

Extreme sizes or wind zones: 10mm/6mm and up

Each step up gives you better wind resistance, less deflection, safer operation, and longer lifespan.

If your doors need 8mm glass to perform safely, we spec 8mm glass. We don’t try to save £200 by fitting thinner glass that’s being pushed to its limits.

How We Actually Do This

Here’s our process, step by step:

1. We assess your site

Location, exposure, building height, door sizes—everything that affects performance.

2. We run the calculations

Using Cortizo’s published data and proper wind load formulas, we work out what your doors will face.

3. We specify correctly

Reinforced interlocks, structural glazing, appropriate glass thickness. If the numbers say you need upgrades, you get upgrades.

4. We explain everything

If additional reinforcement is needed, we show you the calculations and explain exactly what’s required. No technical jargon, no hidden costs, no surprises.

Why This Matters

Properly engineered doors glide smoothly after 20 years, handle severe weather without issues, need minimal maintenance, and deliver consistent performance throughout their lifespan.

Compromised installations develop sticking panels, drafts, hardware failures, and need costly repairs within a few years.

You’re investing £15,000-£30,000+ in doors you’ll use daily. That deserves rigorous engineering, not hopeful assumptions.

The Real Difference

Many companies quote lower prices by using standard components and skipping calculations. Sometimes it works out. Sometimes it doesn’t.

We calculate every specification, select components properly, and follow manufacturer guidelines. The difference between adequate and excellent isn’t always visible immediately—it emerges over years when properly engineered doors keep performing while others develop frustrating problems.

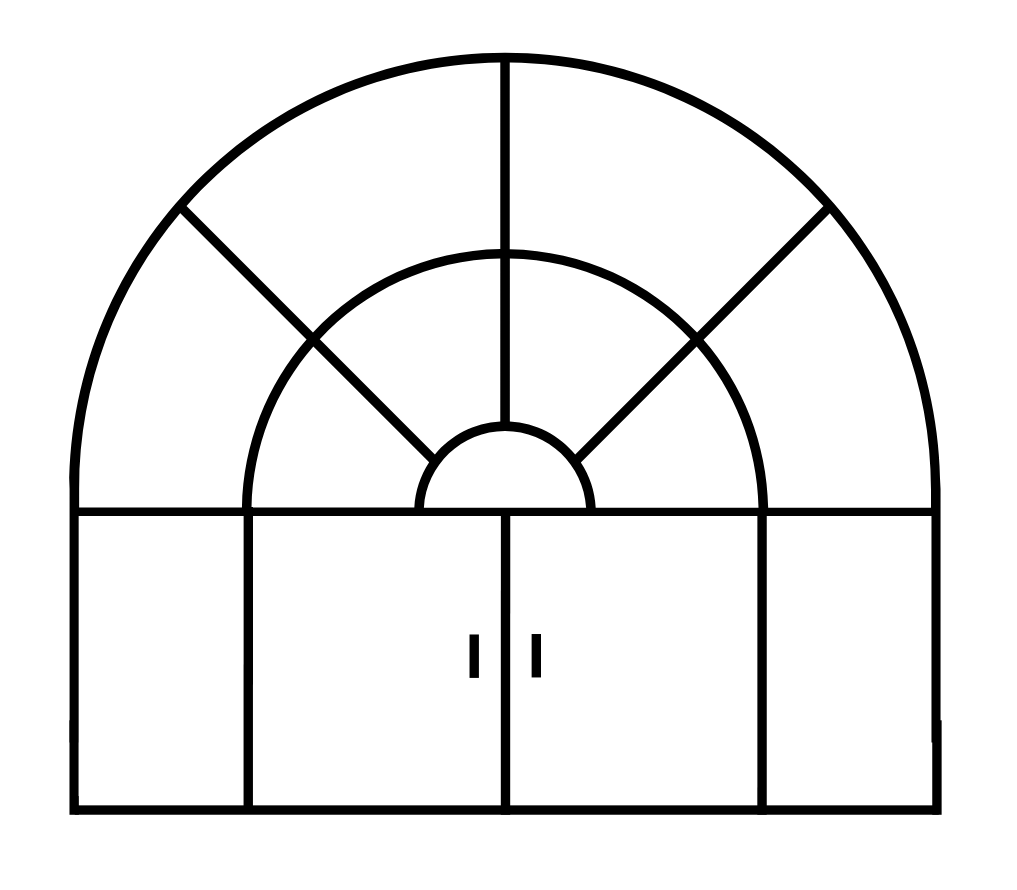

Steel Look Arched Doors

Steel Look Arched Doors Curved Windows

Curved Windows